Flammable gases are explosive when they are mixed with air or oxygen in the right proportions and provided with a source of ignition.

Hydrogen

Hydrogen, a versatile element, plays a pivotal role in reshaping industries and driving decarbonization efforts. In this comprehensive overview, we delve into the diverse applications of hydrogen across various sectors, highlighting its potential and addressing critical considerations.

Applications of Hydrogen Gas

-

Transport

In the evolving landscape of transport, Battery Electric Vehicles (BEVs) are emerging as dominant players across segments, relegating hydrogen's role to long-distance and heavy-duty applications. While BEVs excel in smaller, shorter-range vehicles, Hydrogen Fuel Cell Electric Vehicles (FCEVs) remain competitive in heavier, longer-distance transport, particularly in heavy-duty trucking. The ongoing competition between BEVs and FCEVs underscores the dynamic nature of evolving technologies.

-

Steel Industry

As the main consumer of hydrogen in India, the industry will continue to drive demand, constituting 80% of total hydrogen demand in our Low Carbon scenario. Notably, steel and ammonia production lead hydrogen growth, with green hydrogen poised to compete with natural gas-based ammonia by 2030. The steel industry, a significant driver of green hydrogen demand, is projected to witness competition between green and traditional fossil fuel-based routes. Additionally, a concerted policy push could foster a domestic methanol industry based on green hydrogen.

-

Power Generation

In the power sector, hydrogen emerges as a potential cost-effective solution for inter-seasonal storage in a highly variable renewable electricity system from 2040. As India progresses toward a higher share of wind and solar energy, hydrogen's role as a long-term storage vector becomes essential in managing grid variability at elevated penetrations of variable renewables.

-

Hydrogen Production and System-Wide Considerations

Hydrogen production, an energy-intensive process, must be targeted in sectors where direct electrification is not feasible. Policymakers should prioritize hydrogen deployment in areas with no alternatives, relying on zero-carbon electricity for net emissions reductions. Recognizing the inherent challenges and conversion losses, strategic deployment of hydrogen aligns with environmental sustainability

-

Industrial Clusters and Energy Security

Strategic spatial modeling reveals that industrial clusters present an attractive model for early hydrogen infrastructure development. Focused on low-cost and reliable green hydrogen production, these clusters, such as those in Gujarat and Odisha, showcase the potential for sustainable hydrogen production. Scaling up domestic hydrogen production emerges as a key strategy to significantly reduce India's energy imports, enhancing energy security and reducing dependency on international energy markets.

-

Accelerating Hydrogen Adoption

To accelerate the adoption of hydrogen technologies in India, a transformative shift in government policy and business actions is imperative. Cross-sectoral coordination, commercialization support, emissions penalties, and green product standards are crucial components of the roadmap. The private sector, in collaboration with international technology providers, must play a pivotal role in realizing competitive and sustainable hydrogen projects.

| CAS NO. | 1333-74-0 |

|---|---|

| Molecular Weight | 2.016 |

| Phase at STP | Gas |

| Appearance | Colourless burning with pale blue flaming |

| Odour | Odourless |

| Taste | Tasteless |

| Category | Inflammable |

| Packing | Compressed Gas Cylinders & Manifold Coupled Pallets |

| Grades | Commercial Grade | Ultra High Pure |

|---|---|---|

| Phase | Gas | Gas |

Specification |

||

| Purity | 99.8% | 99.999% |

| Moisture | < 40 mg/m2 | < 2ppm |

| Oxygen | < 0.1% | < 2ppm |

| Nitrogen | < 0.1% | - |

| Carbon Dioxide | < 20ppm | < 0.5ppm |

| Carbon Monoxide | - | < 0.5ppm |

| Total Hydrocarbon | - | < 0.5ppm |

| Mercury | < 0.2 mg/cm | - |

| Packing | Compressed Gas | Compressed Gas |

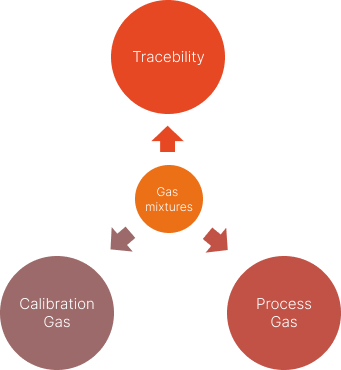

Gas Mixtures

Gas Mixtureare engineered mixtures of gases produced to cater the wide range of industry requirements

The mixture acts as a base for calibration and process control requirements

The mixtures vary from golden standards to binary label mixtures depending on the different tolerance level of the process requirements.